lowest allowable load in brinell hardness test|hardness tester lab report pdf : member club The Brinell hardness test formula. When measuring hardness using the Brinell method, a hardened steel or carbide ball of known diameter under a known load is forced into the . Resultado da Explore os 10 melhores slots para apostas de 5 centavos! Encontre jogos emocionantes e as melhores plataformas para jogar com valores baixos.

{plog:ftitle_list}

Old School Runescape - Gear Table Tool. View the entire collection of old School Runescape equipable items, filter and view their stats side-by-side. BEST IN SLOT .

rockwell hardness tester procedure pdf

The Brinell hardness test is commonly used to determine the hardness of materials like metals and alloys. The test is achieved by applying a known load to the surface of the tested material through a hardened steel ball of known diameter. In the standard method of the Brinell Hardness Test, we use 250 to 500 kg of load for soft material and 500 to 3000 kg of load for hard material such as steel and iron. In the standard method of the test, we use a ball indenter of .The Brinell scale /brəˈnɛl/ characterizes the indentation hardness of materials through the scale of penetration of an indenter, loaded on a material test-piece. It is one of several definitions of hardness in materials science.

1.2 This test method includes requirements for the use of portable Brinell hardness testing machines that measure Brinell hardness by the Brinell hardness test .The Brinell hardness test formula. When measuring hardness using the Brinell method, a hardened steel or carbide ball of known diameter under a known load is forced into the .

volumetric karl fischer titration astm inc

The Brinell hardness test involves indenting a material with a hard sphere under a specific load. Two diameters (x and y axis) of the indentation are measured, and the hardness value is .The Brinell method has a test load range of 1 to 3000 kgf, which means that this method can be used for hardness testing in the low-load and, above all, macro ranges (conventional range). It .

The Brinell hardness lab test method consists of indenting the test material with a 10-mm-diameter hardened steel or carbide ball subjected to a load of 3000 kg. For softer materials, .1. Piling up: Indicates a low rate of hardening by deformation. 2. Sinking: Indicates the ability to work harden. The approximate tensile strength in PSI can be ascertained by multiplying the .Brinell hardness of Gold is approximately 190 MPa. The Vickers hardness test method was developed by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of .

In Brinell tests, a hard, spherical indenter is forced under a specific load into the surface of the metal to be tested. The Brinell hardness number (HB) is the load divided by the surface area of the indentation. The diameter of the impression .Brinell hardness of Aluminium is approximately 240 MPa. The Vickers hardness test method was developed by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. The Vickers hardness test method can be also used as a microhardness test method, which is mostly used for . With the Brinell hardness test, a carbide ball is pressed into the material. The indentation surface serves as a measure of the hardness! . Figure: Too high and too low test loads Load factor. For the above mentioned reasons of too much or too little penetration, the surface pressure between the ball and material sample must therefore not be . The Brinell hardness test measures material hardness by determining the diameter of an indentation made by a hardened steel or carbide ball under a specific load. A load, typically ranging from 500 to 3,000 kgf, is applied to the material’s surface for 10-15 seconds, allowing the ball to penetrate and create an indentation.

Hardness Testing Loads. The hardness testing load is the load (“force”) that is applied to the indenter when pressing into the material being tested. . ASTM E10: This standard covers Brinell hardness testing in metallic samples. ASTM E18: This standard includes the various ways that Rockwell hardness can be measured by standard methods, .

Hardness test methods in the macro range include Brinell, Vickers and Rockwell. Hardness testing in the low-load range applies when the test load falls between an interval of 0.2 kgf and 5 kgf (test load ≥ 0.2 kgf and < 5 kgf). The most commonly used low-load method is Vickers.The Brinell hardness number (HB) is the load divided by the surface area of the indentation. The diameter of the impression is measured with a microscope with a superimposed scale. The Brinell hardness number is computed from the equation: There are a variety of test methods in common use (e.g. Brinell, Knoop, Vickers and Rockwell). There are .Though loads of 500, 1000, 1500, 2000, 2500, and 3000 N are available in a typical Brinell hardness tester, a load of 500 N is used for testing relatively soft metals such as copper and aluminium alloys, while the 3000 N load is often used for testing harder materials such as steels and cast irons. However, the general rule is that the .The Brinell hardness HBW results from the quotient of the applied test force F (in newtons N) and the surface area of the residual indentation on the specimen (the projection of the indentation) after removal of the test force (see Brinell formula).To calculate the surface area of the residual ball indentation, the arithmetic mean d of the two perpendicular diagonals d1 and d2 (in mm) is .

A basic Brinell hardness tester – low-cost and tough enough to withstand the toughest production environments. Duramin 4; DuraVista 40; DuraVersa 100; Duramin 600; Duramin 650; Duramin 3000; . Duramin-3000: Dedicated Single-Task Brinell Hardness Testing Machine Load range: 62.5 – 3000 kgf. Selection Table of Brinell Hardness Test P/D 2. Material type: Brinell hardness number/HB: Sample thickness/mm: Relationship between load P and indenter diameter D: Diameter of indenter D/nm . Vickers hardness test: Low load Vickers test: Micro Vickers hardness test: Hardness symbol: Test force/N: Hardness symbol: Test force/N: Hardness .Brinell hardness test is one of indentation hardness tests, that has been developed for hardness testing. In Brinell tests, a hard, spherical indenter is forced under a specific load into the surface of the metal to be tested. Brinell hardness of Aluminium is approximately 240 MPa.

This standard provides the requirements for a Brinell testing machine and the procedures for performing Brinell hardness tests. 1.2 This standard includes additional requirements in four annexes . For example, currently, both the Rockwell and Brinell hardness standards allow or require the use of tungsten carbide ball indenters; however, all of the ball scale Rockwell hardness tests and most of the Brinell hardness .

hardness tester lab report pdf

hardness test lab report pdf

General Information about the Brinell Hardness Test. The Brinell hardness test involves pressing a hard ball indenter, usually made of tungsten carbide, into the material’s surface with a specified force. The diameter of the .

Put more simply, when using a fixed force (load) and a given indenter, the smaller the indentation, the harder the material. Indentation hardness value is obtained by measuring the depth or the area of the indentation using different test .Indenters for the Brinell hardness test shall be tungsten carbide balls of four allowed diameters (1, 2.5, 5 and 10 mm). Dust, dirt, or other foreign materials shall not be allowed to accumulate on the indenter, as this will affect the test results. Portable Brinell hardness testing machineBrinell hardness test is one of indentation hardness tests, that has been developed for hardness testing. In Brinell tests, a hard, spherical indenter is forced under a specific load into the surface of the metal to be tested. Brinell hardness of Titanium is .This measurement can be conducted using either a low-power microscope or an automatic measuring device. The average diameter value is then utilized to calculate the material's hardness using the Brinell hardness number (BHN). . High-Load Application. The Brinell test also stands out due to its ability to apply higher loads compared to other .

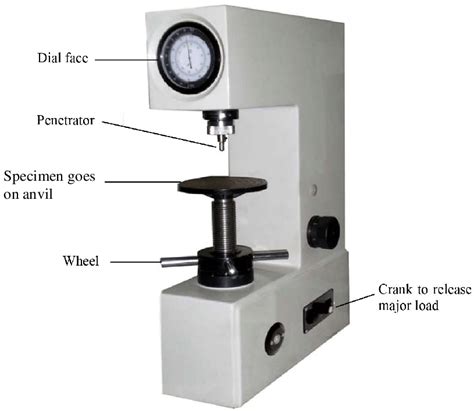

The test provides numerical results to quantify the hardness of a material, which is expressed by the Brinell hardness number – HB. The Brinell hardness number is designated by the most commonly used test standards (ASTM E10-14[2] and ISO 6506–1:2005) as HBW (H from hardness, B from brinell and W from the material of the indenter, tungsten .Rockwell Hardness Test. Rockwell hardness test is one of the most common indentation hardness tests, that has been developed for hardness testing. In contrast to Brinell test, the Rockwell tester measures the depth of penetration of an indenter under a large load (major load) compared to the penetration made by a preload (minor load).

Brinell Hardness Test. The Brinell hardness test is named after its inventor, Johan August Brinell. It involves applying a constant load or force to a spherical indenter made of hardened steel or carbide onto the surface of the material being tested. The indentation diameter is then measured optically.Plug the values of F, D, and d into the formula and calculate the Brinell hardness (HB) in the unit kgf/mm2 or N/mm2. Brinell hardness testing provides an average hardness value over a relatively large area, making it suitable for materials with .

Hardness testing according to current standards. Our hardness testing machines support a wide load range for the Vickers, Brinell and Knoop test methods. All methods are covered with the ISO 6506 / ASTM E10, ISO 6507 / ASTM E384, ASTM E92 and ISO 45452 standards. With the option to extend the load range from 0.25 g to 10 g, we surpass the . 1.5 At the time the Brinell hardness test was developed, the force levels were specified in units of kilograms-force (kgf). Although this standard specifies the unit of force in the International System of Units (SI) as the Newton (N), because of the historical precedent and continued common usage of kgf units, force values in kgf units are provided for information .

A Rockwell hardness tester. The Rockwell scale is a hardness scale based on indentation hardness of a material. The Rockwell test measures the depth of penetration of an indenter under a large load (major load) compared to the penetration made by a preload (minor load). [1] There are different scales, denoted by a single letter, that use different loads or indenters.

volumetric karl fischer titration ppt inc

O conteúdo deste site não poderá ser utilizado em outros site.

lowest allowable load in brinell hardness test|hardness tester lab report pdf